Custom Supreme Sealed Ceramic Glass Fireplace Door

Transform your fireplace with the Ceramic Glass Custom Size Supreme Sealed Masonry Fireplace Door, meticulously crafted to deliver optimal functionality and timeless aesthetic appeal. The Supreme door is engineered to eliminate cold drafts, allowing you to maintain precise control over your fireplace environment.

Features:

- Dual Gasket System: Ensures the glass swinging sections are completely sealed to the outer frame, eliminating drafts and maintaining efficiency.

- Durable Construction: Made from 1/4" steel, this door is built to last and features an exquisite finish for years of trouble-free use.

- Cam Activated Latches: Provides a secure and locked fit for added safety and peace of mind.

- Room Air Inlet: A unique inlet directs air vertically against the glass, creating an air wash that minimizes smoke accumulation and keeps the glass clear.

- Heavy Duty Sealed Door: Fully sealed construction designed for use with both regular heat circulating and radiant heat fireplaces.

Optional Features:

- Handles: Choose from a variety of handle designs, including spring or wood block handles that can be top or bottom-mounted.

- Glass Options: The door comes with ceramic glass, rated to 1400 degrees, ideal for closed-door use and improving heat transfer into the room.

- Fire Screens: Available in sliding or swinging styles, with the sliding screen as the industry standard that can be moved to the sides for fire viewing. The more durable swinging screens can be removed for closed-door use.

- Finishes: Various finishes are available to match your home decor.

Safety and Certification:

- UL 907 and Intertek Tested: The Supreme™ door styles, when ordered with ceramic glass and wood handles, are tested to UL 907 and listed with Intertek, ensuring safe use with your masonry-installed fireplace.

Enhanced Performance:

- Air Wash System: The innovative room air inlet at the base of the door directs air vertically against the glass, reducing smoke buildup and keeping your glass clean longer, thus enhancing your fire viewing experience.

Recommendations:

- Overlap: Each door will be built to overlap the masonry opening by one inch on the sides and top unless specified differently.

- Accurate Measurements: Your custom-built door will be as accurate as the measurements provided. Use a rigid tape or metal ruler for exact measurements.

- Mounting Flange: A mounting flange will protrude into your fireplace opening 2 inches, sized to allow a 1/4” space between it and your masonry opening. This area is used to pack fiberglass insulation to seal the frame to the masonry face. Holes must be site-drilled through this flange into the masonry for attachment.

- Caulking: Use high-temperature silicone or refractory caulking to fill any voids between the door frame and your fireplace.

The Ceramic Glass Custom Size Supreme Sealed Masonry Fireplace Door is the perfect blend of style, durability, and performance. Upgrade your fireplace with this premium door to enjoy a clear view of the flames, improved heat efficiency, and a touch of elegance in your home.

What is a Sealed Fireplace Door?

A sealed fireplace door is designed with high-temperature, continuous woven gaskets that tightly seal the operable door sections to the frame and secure the glass panels in place. This innovative sealing method effectively prevents air from flowing in or out of the fireplace.

Benefits:

- Prevents Excess Air Flow and Drafts: Stops unwanted air and cold drafts from entering the room.

- Fire Control: Provides better control over the fire, enhancing safety and efficiency.

- Reduces Odor: Minimizes fireplace odors when the fireplace is not in use.

- Energy Efficiency: Lowers heating and cooling costs by maintaining a more stable indoor temperature.

- Eliminates Back Smoking: Prevents smoke from entering the room even at negative pressure levels exceeding -25 PA, making it suitable for wood-burning fireplaces in regions with strict building codes.

Sealed fireplace doors are an excellent solution for enhancing the functionality and energy efficiency of traditional wood-burning fireplaces.

Features:

- Warranty: 5-year warranty on workmanship and materials, and a 10-year warranty on ceramic glass against heat breakage.

- Air Sealed Door: Available in overlap fit or inside fit options.

- Finish Options: Elegant satin black frame finish, with additional stove bright color options available.

- Heavy-Duty Construction: 1/4 inch thick steel frame with a slotted damper.

- Sturdy Cabinet Doors: Fully encased 3/16 inch thick ceramic glass.

- Handle Choices: Select from black or brass spring handles or wood block handles.

- Mesh Protection: Not included, but upgrades are available.

- Fully Assembled: Comes with all necessary mounting hardware.

- Energy Efficient: Proven to eliminate back smoking at negative pressure levels exceeding -25 PA.

- Safety Tested: Door styles are tested to UL 907 standards and listed with Intertek testing when ordered with ceramic glass and wood handles.

Specifications:

- Door Fit: Overlap | Inside

- Door Type: Cabinet Doors

- Material: 1/4" Heavy Steel Frame

- Approximate Overlap: 1" On Overlap doors, inside fit doors don't overlap

- Recessed Depth: 2"

- Main Frame Finish: Satin Black

- Door Frame Finish: Satin Black

- Glass: 3/16 Ceramic Glass

- Mesh Protection: Not Included (Upgrades Available)

- Draft Assembly: Slotted Damper Optional

- Gasketed Sealed Option: Yes

- Assembly: Fully Assembled

- Handle: Black Spring Handle | Brass Spring Handle | Nickel Handle | Wood Block

- Mounting: Hardware Included

- Door styles are tested to UL 907 and listed with Intertek testing when ordered with ceramic glass and wood handles!

- 10-year warranty on ceramic glass against breakage due to heat

Downloads:

- Custom Supreme Sealed Ceramic Glass Masonry Fireplace Door

- How To Measure For Your Masonry Fireplace Door

Stove Bright Color Chart:

1. The tools required for installation: a power drill, a 1/4" metal drill bit, a 3/16" masonry drill bit, a 5/16" socket with ratchet, a caulking gun, hi-temp silicone and safety glasses. Always wear safety glasses during installation to prevent unwanted objects in your eyes. Use properly grounded electrical cords to prevent electrical shock.

2. The door installation kit includes: an insulation strip, self tapping masonry lag screws and 2-wooden handles.

3. Remove all parts and protective packing from the door carton.

4. WARNING! This door frame must be installed PLUMB!! DO NOT FORCE THE DOOR TO FIT IRREGULAR OPENINGS!! This will cause misalignment of the glass sections and a poor seal will result. Plumb the masonry front with cement or fill the void with insulation. All doors are factory fit on a plumb surface to verify alignment and fit of the doors.

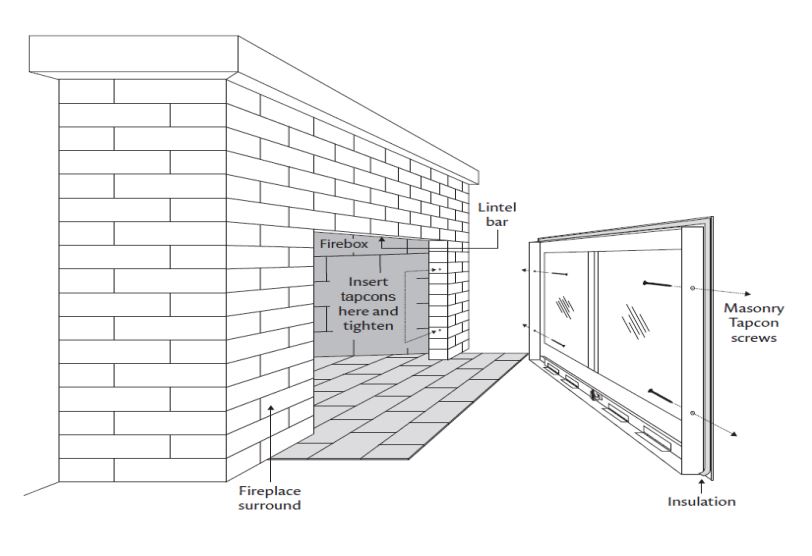

5. Measure the sides of the opening to determine where cement joints exist. Drill the builders flange using the 1/4" metal drill bit at the appropriate joint heights and in ½ inch from the back side of the builders flange. Usually, the lowest holes are up approximately 8" from the hearth line. Drill the top holes approximately 2" down from the lintel iron. See the illustration on the back of this page. Place the door frame into the opening and mark the cement seams where the holes have been made in the builders flange. Remove the frame and drill holes into these marked areas with the 3/16" masonry bit. These holes must extend in as deep as the lag screws.

6. Reposition the frame into the opening and start the masonry lags in the holes. Set the door frame in the opening and center left to right. Insert the fiberglass seal between masonry and the builders flange. Tighten the screws into the masonry cement using the 5/16" socket and ratchet. Verify that the door frame is plumb. Place the doors on the hinges and re-plumb if doors are out of alignment. Tighten all mounting screws evenly.

7. Use Hi-temp silicone to seal the inner perimeter of the builders flange to the fireplace facing for maximum sealing, avoiding contact with the outside finished front of doors and frame.

8. If a bottom mounted block wood handle is used, place several drops of crazy glue in the handle hole to permanently attach the wood handle to the door latch. The flat non-milled side of handle goes toward the door. Glue contacting the door or frame finish may discolor this finish.

No reviews found